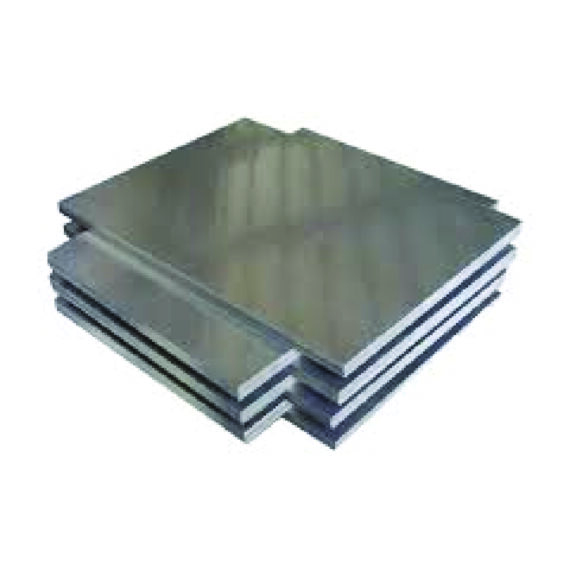

904L Stainless Steel Plates are commonly used in various industries such as chemical processing, oil and gas, pharmaceuticals, and food processing. They offer excellent resistance to corrosion and pitting in harsh environments and high temperatures.

These plates have a high alloy composition, including chromium, nickel, and molybdenum, which provide excellent corrosion resistance and durability. They are also suitable for use in heat exchangers, flue gas desulfurization equipment, and seawater cooling systems.

Featuers of SS 904L Plates

Some of the key features of Stainless Steel 904L Plates are

- Corrosion resistance: SS 904L Plates are known for their excellent resistance to corrosion, particularly in non-oxidizing acids such as sulfuric acid. They are suitable for use in harsh environments and high temperatures.

- High-alloy composition: These plates have a high alloy composition, including chromium, nickel, and molybdenum, which provide excellent corrosion resistance and durability.

- Low carbon content: The low carbon content in SS 904L Plates makes them less prone to sensitization and corrosion.

- Durability: The high-alloy composition of SS 904L Plates provides increased durability, making them resistant to wear and tear even in harsh conditions.

- Weldability: These plates are easy to weld and form, which makes them suitable for a wide range of applications.

- Machinability: SS 904L Plates can be easily machined, making them ideal for various industrial applications.

- Smooth surface finish: These plates have a smooth surface finish, which makes them aesthetically pleasing and easy to clean.

Stainless Steel 904L Plates offer excellent corrosion resistance, high-alloy composition, low carbon content, durability, weldability, machinability, and smooth surface finish, making them suitable for various industrial applications.

Application of Stainless Steel 904L Plates

Stainless Steel 904L Plates has a wide range of applications in various industries due to their excellent resistance to corrosion and high-temperature strength.

Some of the common applications of SS 904L Plates are;

- Chemical processing: SS 904L Plates are commonly used in chemical processing equipment such as heat exchangers, tanks, and reactors due to their excellent resistance to corrosion in harsh chemical environments.

- Oil and gas: SS 904L Plates are used in the oil and gas industry for the manufacturing of pipes, heat exchangers, and storage tanks due to their high resistance to corrosion and pitting.

- Pharmaceuticals: SS 904L Plates are used in the pharmaceutical industry for the manufacturing of equipment such as reactors, tanks, and mixing vessels due to their excellent corrosion resistance and low carbon content.

- Marine applications: SS 904L Plates are suitable for use in seawater cooling systems, heat exchangers, and piping systems due to their high resistance to corrosion in marine environments.

- Food processing: SS 904L Plates are used in the food processing industry for the manufacturing of equipment such as food storage tanks, mixing tanks, and food processing equipment due to their smooth surface finish and excellent corrosion resistance.

- Pulp and paper industry: SS 904L Plates are used in the pulp and paper industry for the manufacturing of equipment such as digesters, evaporators, and bleaching equipment due to their high resistance to corrosion in harsh chemical environments.

Stainless Steel 904L Plates are widely used in various industrial applications such as chemical processing, oil and gas, pharmaceuticals, marine applications, food processing, and the pulp and paper industry due to their excellent resistance to corrosion and high-temperature strength.

ASTM B625 TP904L Stainless Steel Plates Equivalent Grades

| STANDARD | UNS | WERKSTOFF NR. | KS | JIS | BS | AFNOR | EN |

| SS 904L | N08904 | 1.4539 | STS 317 J5L | SUS 904L | 904S13 | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

UNS N08904 Stainless Steel Plates Chemical Composition

| Grade | C | Ni | Si | Mo | P | S | Mn | Cr | CU | |

| SS 904L | Min | – | 23.00 | – | 4.00 | – | – | – | 19.0 | 1.00 |

| max | 0.20 | 28.00 | 1.00 | 5.00 | 0.045 | 0.035 | 2.00 | 23.0 | 2.00 |

Mechanical Properties of 904L Stainless Steel SS 904L Plates

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) |

Elongation |

| 7.95 g/cm3 | 1350 °C (2460 °F) | Psi – 71000, MPa – 490 | Psi – 32000, MPa – 220 | 35 % |

Our staff of skilled, qualified, and experienced workers is in charge of overseeing every step of the production process to avert errors and defects. They monitor every step of the process, from choosing the materials to sending the plates. At every stage of production, our quality testers confirm the characteristics and all pertinent criteria of SS 904L Plates by performing various destructive and non-destructive tests.

Likewise, Hilton Forge India considers all of its specifications when producing exact SS 904L Plates for various industrial industries. Together with upholding better quality standards, we also take care of shipping and packing. By using the proper packaging materials to wrap these SS 904L Plates and choosing a rapid method, we ensure that shipping will be simple and convenient.

City We Supply Types of Stainless Steel Plates Suppliers

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | Kanpur |

| Thane | Bhopal | Sri City | Bareilly | Hosdurg | Pithampur |

Countries We Supply and Export Types of Stainless Steel Plates Suppliers

| Saudi Arabia | Oman | Kuwait |

| Bahrain | Qatar | UAE |

| Nigeria | Mexico | Canada |

| India | Tanzania | Belgium |

| United States | South Africa | Malaysia |

| Singapore | Sri-Lanka | Australia |

| France | Italy | South Korea |

| Netherlands | Africa | Germany |

| Poland | Turkey | Brazil |

| Iran | China | United Kingdom |

Reviews

There are no reviews yet.