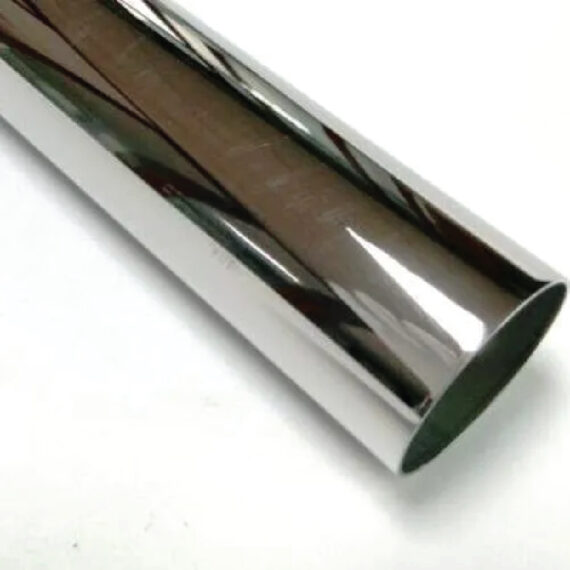

Stainless Steel 317/317L Pipes are high-quality, austenitic stainless steel pipes made from an alloy containing chromium, nickel, and molybdenum. The addition of molybdenum enhances the corrosion resistance of these pipes in corrosive environments containing sulfuric acid and chloride ions.

Stainless Steel 317L Pipes have a lower carbon content than Stainless Steel 317 Pipes, which makes them suitable for welding applications. These pipes are available in various sizes, shapes, and thicknesses to meet the diverse needs of different industrial and commercial piping applications. They offer high-temperature strength and excellent resistance to pitting, crevice corrosion, and stress corrosion cracking.

Overall, Stainless Steel 317/317L Pipes are a reliable and cost-effective option for a wide range of piping applications where durability, strength, and corrosion resistance are essential.

Featuers of Stainless Steel 317 Pipes

Stainless Steel 317 Pipes have several desirable properties that make them suitable for a wide range of industrial and commercial piping applications.

Stainless Steel 317/317L Pipes are high-quality pipes made from an austenitic stainless steel alloy with a higher molybdenum content than conventional stainless steel pipes.

Here are some of the key features of Stainless Steel 317/317L Pipes:

- Corrosion Resistance: Stainless Steel 317/317L Pipes have excellent resistance to corrosion, particularly in acidic environments containing sulfuric acid and chloride ions. This property makes them ideal for use in chemical processing, petrochemicals, and refining industries.

- High-Temperature Strength: Stainless Steel 317/317L Pipes can withstand high temperatures up to 1000°C, making them suitable for use in high-temperature applications such as boilers, heat exchangers, and steam pipes.

- Pitting and Crevice Corrosion Resistance: Stainless Steel 317/317L Pipes are highly resistant to pitting and crevice corrosion, making them suitable for use in seawater applications and other harsh environments.

- Low Carbon Content: Stainless Steel 317L Pipes have a lower carbon content than Stainless Steel 317 Pipes, making them suitable for welding applications.

- Good Formability: Stainless Steel 317/317L Pipes are easy to fabricate and can be welded and formed into various shapes and sizes, making them suitable for a wide range of piping applications.

- High Strength: Stainless Steel 317/317L Pipes have high strength and durability, making them suitable for use in applications that require reliable and long-lasting pipes.

Overall, Stainless Steel 317/317L Pipes are a versatile and reliable option for a wide range of industrial and commercial piping applications where resistance to corrosion, high-temperature strength, and durability are critical.

Application of Stainless Steel 317/317L Pipes

Stainless Steel 317/317L Pipes has a wide range of applications in various industries, including

- Chemical Processing

- Petrochemicals

- Refineries

- Heat Exchangers

- Boilers

- Food and Beverage Industry

- Pharmaceuticals, and so on

ASME SA 312/SA 213TP317L Pipe Equivalent Grades

| STANDARDS | WERKSTOFF NR. | UNS | JIS | EN |

| SS 317 | 1.4449 | S31700 | SUS317 | – |

| SS 317L | 1.4438 | S31703 | SUS317L | X2CrNiMo18-15-4 |

SS 317/317L Pipes Chemical Composition

| GRADE | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 317 | 0.08 max | 2 max | 1 max | 0.045 max | 0.030 max | 18-20 | 3-4 | 11-15 | 57.845 min |

| SS 317L | 0.035 max | 2 max | 1 max | 0.045 max | 0.030 max | 18-20 | 3-4 | 11-15 | 57.89 min |

Stainless Steel 317/317L Pipes Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength(0.2%offset) | Elongation |

| 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000, MPa – 515 | Psi – 30000, MPa – 205 | 35 % |

Our experienced and skilled experts are supervising the manufacturing process to ensure its integrity and the absence of defects and errors. They observe the process right from the selection of material to the final dispatch of Pipes. Our quality testers ensure the qualities and all necessary parameters of SS 317/317L Pipes at every stage of production by performing various destructive and non-destructive tests.

Moreover, Hilton Forge India is considering all requirements of various industrial sectors to produce exact SS 317/317L Pipes for them. We are not only maintaining quality standards higher, but we are also taking care of packing and shipping. We pack these SS 317/317L Pipes in suitable packing materials, and by choosing a fast way of transportation, we ensure to offer smooth and convenient doorstep service within the decided time.

City We Supply Types of Stainless Steel Pipes suppliers

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | Kanpur |

| Thane | Bhopal | Sri City | Bareilly | Hosdurg | Pithampur |

Countries We Supply and Export Types of Stainless Steel Pipes suppliers

| Saudi Arabia | Oman | Kuwait |

| Bahrain | Qatar | UAE |

| Nigeria | Mexico | Canada |

| India | Tanzania | Belgium |

| United States | South Africa | Malaysia |

| Singapore | Sri-Lanka | Australia |

| France | Italy | South Korea |

| Netherlands | Africa | Germany |

| Poland | Turkey | Brazil |

| Iran | China | United Kingdom |

Reviews

There are no reviews yet.