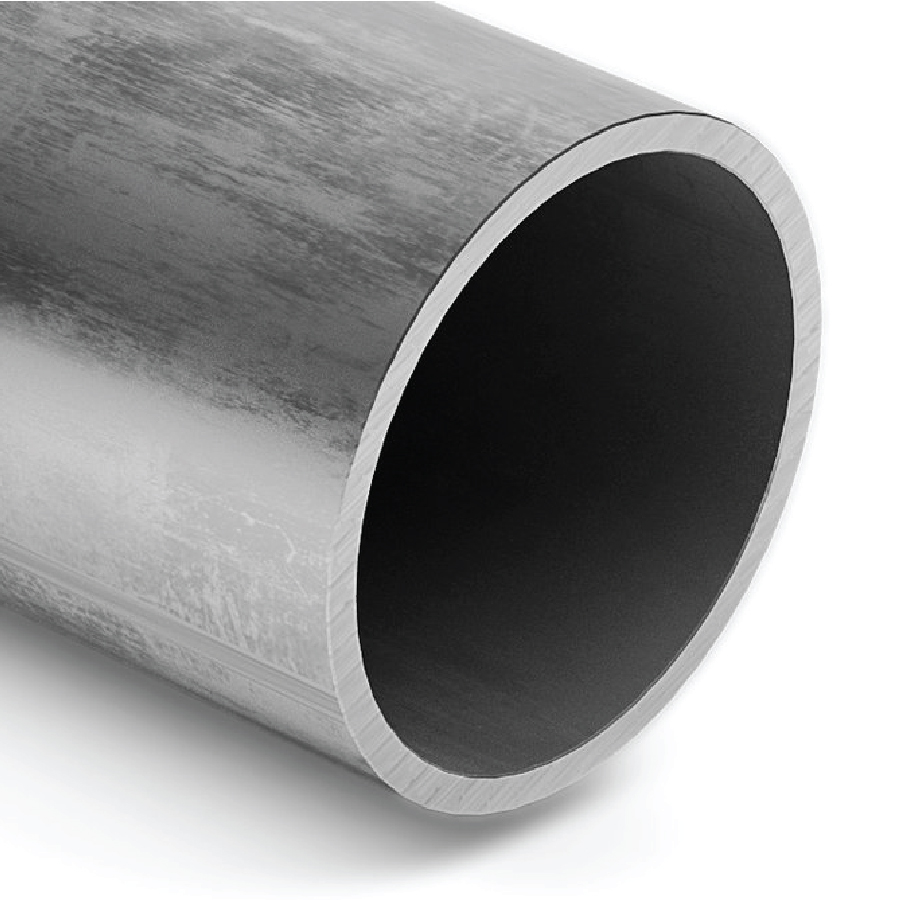

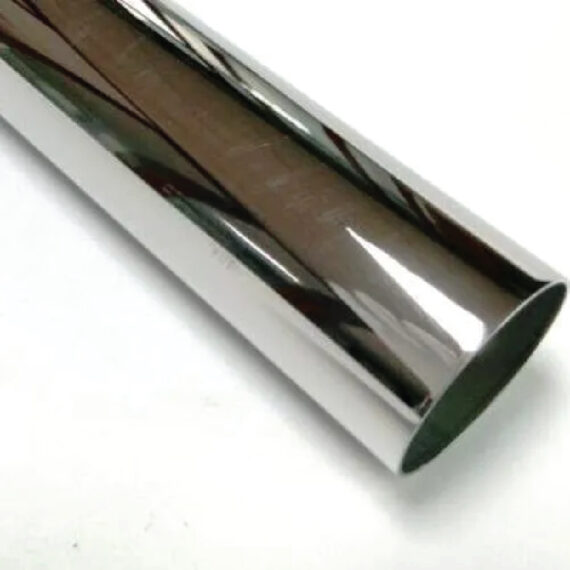

Featuers of SS 321/321h Pipes

Stainless steel 321/321H pipes have several features that make them an ideal choice for industrial and commercial piping applications.

Here are some of the key features of SS 321/321H pipes:

- Excellent Corrosion Resistance: These pipes offer excellent resistance to corrosion, making them ideal for use in harsh environments, particularly in high-temperature applications.

- High-Temperature Strength: Stainless steel 321/321H pipes are designed to withstand high temperatures, which makes them suitable for use in high-temperature applications such as chemical processing, refineries, and power generation.

- Good Weldability: These pipes are easy to weld, which makes them ideal for use in situations where welding is required, such as in the construction of pipelines or in manufacturing processes.

- Formability: These pipes can be easily formed and fabricated, which allows them to be customized to meet specific requirements.

- Durability: Stainless steel 321/321H pipes are highly durable and can withstand the rigors of daily use, making them a reliable and long-lasting option for industrial and commercial piping applications.

- Resistance to Scaling and Creep: Stainless steel 321/321H pipes are known for their resistance to scaling and creep at high temperatures, which makes them ideal for use in high-temperature applications where other metals may fail.

- Higher Carbon Content: The 321H variant has a higher carbon content, which provides improved high-temperature strength and greater resistance to sensitization.

Overall, the combination of excellent corrosion resistance, high-temperature strength, good weldability, formability, durability, resistance to scaling and creep, and higher carbon content in the 321H variant make stainless steel 321/321H pipes an excellent choice for a wide range of piping applications, particularly those involving high-temperature environments.

Application of SS 321/321h Pipes

Stainless steel 321/321H pipes is widely used in a variety of industrial and commercial applications due to their excellent corrosion resistance, high-temperature strength, and other desirable properties.

Here are some of the common applications of SS 321/321H pipes:

- Chemical Processing

- Refineries

- Power Generation

- Aerospace

- Food Processing

- Medical Equipment and so on

Overall, stainless steel 321/321H pipes are versatile and reliable options for a wide range of industrial and commercial applications where resistance to corrosion and high temperatures is critical.

ASME SA 312 / SA 213 TP 321/321H Pipe Equivalent Grades

| STANDARD | WERKSTOFF NR | UNS | JIS | EN |

| SS 321 | 1.4541 | S32100 | SUS321 | X6CrNiTi18-10 |

| SS 321H | 1.4878 | S32109 | SUS 321H | X12CrNiTi18-9 |

SS 321/321H Pipes Chemical Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | N | Ni | Ti |

| SS 321 | 0.08 max | 2 max | 1 max | 0.045 max | 0.030 max | 17-19 | 0.10 max | 9-12 | 5(C+N) – 0.70 max |

| SS 321H | 0.04 – 0.10 | 2 max | 1 max | 0.045 max | 0.030 max | 17-19 | 0.10 max | 9-12 | 4(C+N) – 0.70 max |

Stainless Steel 321 / 321H Pipe Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000, MPa – 515 | Psi – 30000, MPa – 205 | 35 % |

Our team of skilled and experienced professionals supervise the entire manufacturing process to avoid defects and errors, from the selection of materials to the dispatch of the SS 321/321h Pipes. Quality testers ensure the quality standards and parameters of the pipes at each stage of production by conducting various destructive and non-destructive tests. Additionally, Hilton Forge India takes into consideration all the requirements of the various industrial sectors in order to produce the perfect SS 321, 321h Pipes. Not only do we strive to maintain the highest quality standards, but we also take care of the packing and shipping. We securely pack the SS 321/321h Pipes in suitable packing materials and employ a fast transportation method to ensure a smooth, convenient doorstep service within the designated time frame.

Reviews

There are no reviews yet.